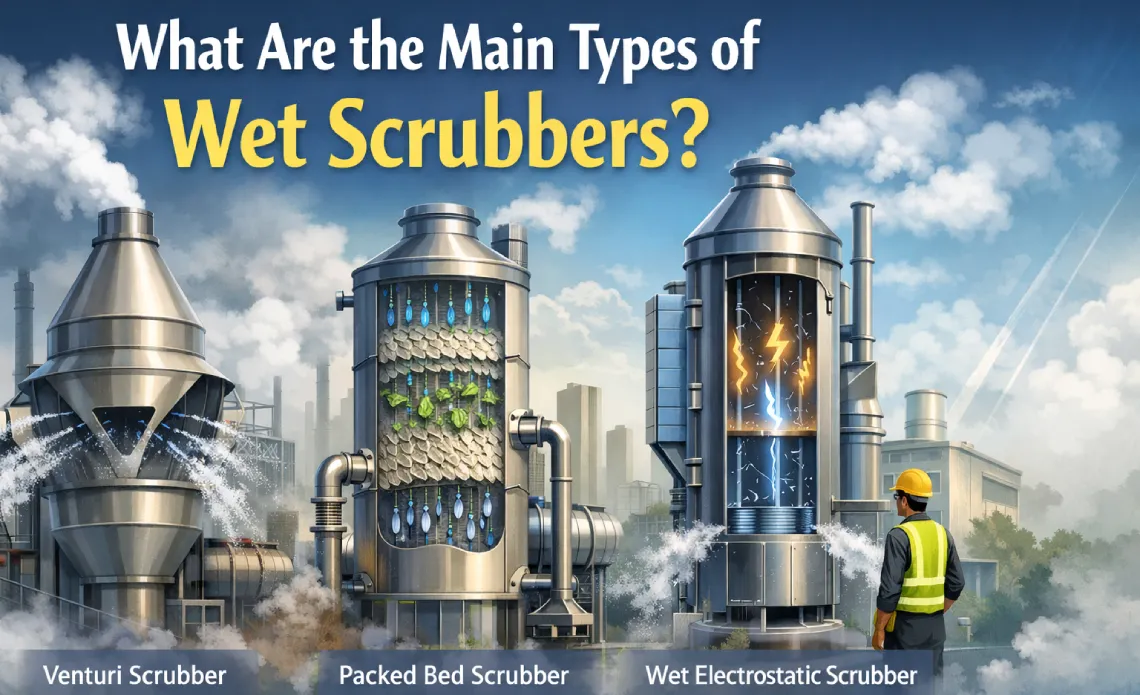

What Are the Main Types of Wet Scrubbers?

Industrial air pollution remains a critical global concern. Factories and processing plants release harmful contaminants into the atmosphere. Regulatory bodies enforce strict emission limits to protect public health. Therefore, industries must adopt effective control technologies. Wet scrubbers stand out as a versatile and powerful solution. They use liquid to capture pollutants from gas streams. Understanding the various Types of Wet Scrubbers helps you make informed decisions. Each design serves specific applications and contaminant profiles.

At UK Enviro Systems, we engineer high-performance scrubbing systems. Our solutions help industries achieve compliance while maintaining productivity. This guide explores the primary wet scrubber configurations available today.

Table of Contents

ToggleThe Fundamental Operating Principle

Wet scrubbing relies on gas-liquid contact. The process transfers pollutants from the gas phase to the liquid phase. This liquid then carries the contaminants away for treatment or disposal. The method handles both particulate matter and gaseous pollutants effectively. It proves especially useful for sticky, flammable, or corrosive materials.

Key Mechanisms at Work

Several physical mechanisms drive the cleaning process. Impaction occurs when particles collide with liquid droplets. Diffusion captures very fine particles through random motion. Absorption dissolves soluble gases into the liquid. Chemical reactions can neutralize acid gases on contact. The scrubber design maximizes these interactions for optimal efficiency.

Spray Tower Scrubbers: Simplicity and Reliability

Spray towers represent the most straightforward design among wet scrubbers. They consist of an empty cylindrical vessel with spray nozzles. These nozzles distribute liquid throughout the gas stream.

How Spray Towers Function

Contaminated gas typically enters the bottom of the tower. It flows upward while liquid sprays downward from multiple levels. This counter-current flow pattern maximizes contact opportunity. The droplets capture particles and absorb gases as they fall. Clean gas exits the top while liquid collects in a bottom sump. The liquid then recirculates through the system.

Advantages of This Design

Spray towers handle large gas volumes with ease. They have very low pressure drop, saving energy costs. Their simple construction means minimal maintenance requirements. They handle high particulate loads without clogging. However, they offer limited efficiency for fine particles. They also provide less gas absorption than other designs. They work best as pre-cleaners or for easily captured pollutants.

Packed Bed Scrubbers: Enhanced Mass Transfer

Packed bed scrubbers build upon the spray tower concept. They add specialized media inside the vessel to increase surface area.

The Role of Packing Material

The packing material creates a wetted surface for gas-liquid contact. Random packing consists of small shapes dumped into the column. Common shapes include rings, saddles, and spheres. Structured packing uses arranged sheets or grids. Both types force gas to follow a tortuous path. Liquid spreads thinly over all packing surfaces. This maximizes the contact area within a compact volume.

Counter-Current Operation

Gas enters at the bottom and flows upward through the packing. Liquid distributes over the top and trickles downward. This counter-current flow maintains a strong concentration gradient. The cleanest gas contacts freshest liquid at the top. This arrangement achieves high removal efficiencies for soluble gases. As experienced FRP Scrubber Manufacturers, we often recommend packed towers for acid gas control. They excel at removing hydrogen chloride, sulfur dioxide, and ammonia. They also handle organic vapors with appropriate chemical reagents.

Venturi Scrubbers: Power for Fine Particulates

Venturi scrubbers address the challenge of sub-micron particles. They use high velocity to create intense gas-liquid mixing.

The Venturi Geometry

The scrubber features a unique shape with three sections. Gas enters a converging section that increases velocity. It then passes through a narrow throat where maximum speed occurs. Liquid injects at or before the throat. The high-speed gas atomizes this liquid into fine droplets. Gas then enters a diverging section that recovers pressure and slows flow.

Particle Capture Mechanism

The velocity difference between gas and droplets drives collection. Particles cannot follow the gas streamlines around droplets. They impact directly onto the droplet surface due to inertia. Smaller droplets capture smaller particles more effectively. The intense turbulence ensures billions of collision opportunities. This design achieves over 99% efficiency for fine particles. It handles sticky or explosive dusts where baghouses pose risks. Many Scrubber for Pollution Control applications rely on Venturi technology. However, the high pressure drop increases energy consumption significantly.

Plate and Tray Towers: Staged Cleaning

Plate towers, also called tray towers, use horizontal stages inside a vertical column. Each stage provides discrete gas-liquid contact.

How Trays Operate

Liquid flows across each tray and down to the next level. Gas rises through openings in the tray floor. These openings may be simple holes, valves, or bubble caps. Gas disperses into the liquid, creating a froth or bubbling zone. This intimate mixing occurs on every tray. The gas becomes progressively cleaner as it rises through each stage.

Applications for Staged Contact

Plate towers handle high liquid flow rates effectively. They suit processes requiring multiple theoretical stages. They resist fouling better than packed beds for dirty gases. Solids in the gas stream can plug packing, but trays remain accessible. They work well for difficult separations requiring high efficiency. They serve chemical processing, refining, and gas treatment applications.

Mechanically Aided Scrubbers: Integrated Design

Mechanically aided scrubbers combine fan and scrubber functions. They use rotating components to create droplets and move gas.

This design integrates the fan wheel into the scrubber. Water sprays directly onto the rotating fan blades. The high-speed blades atomize the liquid into fine droplets. Particles impact onto wetted surfaces and collect. Centrifugal force throws liquid and captured material outward. This compact design suits space-constrained installations. It provides both gas movement and cleaning in one unit.

Some configurations use a rotor partially submerged in liquid. The spinning rotor generates a dense spray field. Gas passes through this spray zone for particle collection. These units operate with low liquid-to-gas ratios. However, moving parts face corrosion and wear. Maintenance requirements exceed those of static designs. They offer limited gas absorption capability due to short contact time.

Key Selection Factors

Choosing the right scrubber requires careful analysis. Several factors influence the final decision.

Pollutant Characteristics

The type and size of contaminants matter greatly. Gaseous pollutants need absorption, favoring packed towers. Fine particles need high energy, favoring Venturi designs. Mixed streams may require hybrid configurations. Understanding your specific emissions drives the choice among Types of Wet Scrubbers.

Operating Conditions

Gas temperature, humidity, and flow rate affect performance. High temperatures may require special materials or quench sections. Variable flow rates demand flexible designs. Space constraints may favor compact mechanically aided units. Existing ductwork and fan capacity influence pressure drop tolerance.

Material Compatibility

Corrosion resistance determines system longevity. FRP construction resists a wide range of chemicals. It proves ideal for acid gas scrubbing applications. Stainless steel suits certain applications but may corrode with chlorides. Leading FRP Scrubber Manufacturers understand these material interactions. They specify the right resin system for each application. If searching for an FRP Scrubber Near Me, verify their material expertise.

Auxiliary System Components

A complete scrubber system includes more than the main vessel. Supporting equipment ensures reliable operation.

Recirculation Pumps

Pumps move scrubbing liquid from the sump to spray headers. They must maintain proper flow and pressure continuously. Redundant pumps provide backup for critical applications. Pump material must resist corrosion and abrasion from captured solids.

Mist Eliminators

Gas leaving the scrubber carries entrained liquid droplets. Mist eliminators capture this liquid before exhaust. Common designs include chevron blades and mesh pads. Proper demister selection prevents visible plumes. It also protects downstream fans and ductwork from moisture.

Chemical Feed Systems

Many applications require chemical reagents for effective removal. Caustic soda neutralizes acid gases effectively. Oxidizers like sodium hypochlorite destroy odorous compounds. pH control systems maintain proper chemical strength. Automated feed reduces operator workload and chemical waste.

Instrumentation and Controls

Modern scrubbers include comprehensive monitoring systems. Pressure transmitters track pressure drop across the bed. pH sensors control chemical feed rates. Flow meters verify proper liquid distribution. PLC-based automation adjusts operation for varying loads. Data logging supports compliance reporting requirements.

Applications Across Industries

Wet scrubbers serve diverse industrial sectors worldwide. Their versatility makes them indispensable for emission control.

Chemical Processing

Chemical plants generate acid gases, organic vapors, and particulates. Reactor vents and storage tank emissions require treatment. Packed towers with chemical reagents provide reliable control. They handle variable loads and maintain compliance continuously.

Metal Finishing

Plating operations release chromic acid mist and metal compounds. Scrubbers capture these toxics at the source. They protect workers from exposure. They prevent environmental releases that invite regulatory action.

Pharmaceutical Manufacturing

Drug production creates solvent vapors and active compounds. Scrubbers capture these emissions before release. They recover valuable materials in some applications. They ensure facilities remain good neighbors.

Wastewater Treatment

Treatment plants generate hydrogen sulfide and other odorous gases. Scrubbers using caustic and oxidizers eliminate odors effectively. They keep facilities welcome in their communities. They protect workers from toxic gas exposure.

Power Generation

Combustion sources emit sulfur dioxide and particulates. Large scrubbers, often called FGD systems, control these emissions. They enable coal and oil use within environmental limits.

Maintenance Best Practices

Regular maintenance ensures long-term scrubber performance. A proactive approach prevents unexpected downtime.

Daily Visual Checks

Operators should inspect all external components daily. Check pumps for leaks and unusual noises. Verify pressure gauges show normal readings. Ensure chemical feed systems have adequate supply.

Weekly Inspections

Inspect spray nozzles for wear or plugging weekly. Check mist eliminators for solids buildup. Verify instrument calibration against known standards. Record all readings in a maintenance log.

Monthly Maintenance

Lubricate pump bearings according to manufacturer specifications. Inspect packing condition through access ports. Check FRP surfaces for cracking or delamination. Address minor damage before it progresses.

Annual Overhaul

Schedule comprehensive inspection during planned outages. Remove and inspect internal components thoroughly. Clean packing or trays to restore performance. Replace worn nozzles and gaskets. Test all instruments and controls.

Advances in Scrubber Technology

The field continues evolving with new materials and controls.

Improved Packing Designs

Modern packing offers higher efficiency with lower pressure drop. Structured packing provides predictable performance. Surface enhancements increase mass transfer rates. New materials resist fouling and corrosion better.

Advanced Control Systems

PLC-based automation optimizes chemical feed continuously. Remote monitoring allows off-site oversight. Data logging simplifies compliance reporting. Predictive maintenance alerts prevent unexpected failures.

Hybrid Configurations

Combining scrubber types optimizes performance for challenging streams. A Venturi ahead of a packed tower handles both particles and gases. This approach ensures comprehensive control in a single system.

Conclusion

Wet scrubbers provide proven, reliable air pollution control. Understanding the main types helps you select the right solution. Spray towers offer simplicity for easy applications. Packed bed scrubbers excel at gas absorption with efficient mass transfer. Venturi scrubbers tackle fine particles with high energy input. Plate towers provide staged contact for difficult separations. Mechanically aided designs offer compact, integrated packages.

Each design serves specific needs and operating conditions. Pollutant characteristics, gas flow, and efficiency targets guide selection. Material compatibility ensures long service life in corrosive environments. Proper maintenance preserves performance over decades of service. Partnering with experienced FRP Scrubber Manufacturers guarantees a system tailored to your needs. At UK Enviro Systems, we deliver top-quality Wet Scrubbers for global industries. We design Fume Extraction Systems that meet the strictest standards. Contact us to discuss your specific application. Let us help you protect your workers, your community, and our shared environment.