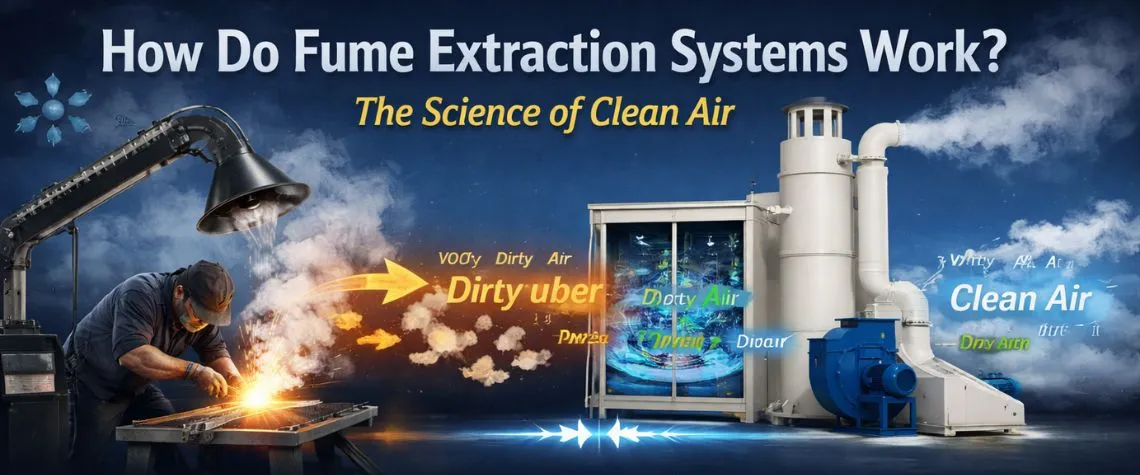

How Do Fume Extraction Systems Work? Unveiling the Science of Clean Air

Table of Contents

ToggleHow Fume Extraction Systems Work

Every day, industrial processes create invisible clouds of hazardous fumes and particulates. These pollutants pose serious risks to both human health and the environment. Effective Fume Extraction Systems are the essential engineering solution. They capture, contain, and clean contaminated air directly at its source. This proactive process ensures workplace safety and regulatory compliance. At UK Enviro Systems, we engineer these critical systems for superior performance. We will explore the fascinating science that turns polluted air into clean, safe breathable air.

The Critical Need for Industrial Air Filtration

Firstly, understanding the “why” underscores the importance of the “how.” Manufacturing, welding, chemical processing, and plating all generate dangerous emissions. These emissions include toxic gases, fine dust particles, and corrosive mists. Without intervention, they degrade air quality and damage equipment. More importantly, they cause severe respiratory problems for personnel. Consequently, robust fume control is not a luxury. It is an absolute necessity for responsible and sustainable industrial operations.

Core Principles of Fume Capture and Extraction

All effective systems operate on two fundamental principles: capture and containment. The process begins at the very point where fumes originate. This is typically achieved using precisely positioned capture hoods or enclosures. Then, a powerful fan generates consistent negative airflow. This airflow pulls the contaminated fumes into a dedicated duct network. Therefore, the pollutants never disperse into the general workspace. This contained stream of dirty air then travels to the cleaning unit.

The Workhorse of Air Cleaning: Wet Scrubber Technology

The most common and versatile cleaning devices are wet scrubbers. Fume Extraction Systems often rely on this proven technology. But how does a Wet Scrubber for Pollution Control actually work? The science involves intimate contact between the dirty gas and a liquid scrubbing solution.

The Contaminant-Liquid Interaction

Polluted air enters the scrubber vessel at high velocity. Inside, it encounters a shower or mist of the scrubbing liquid, often water or a chemical reagent. Here, a transfer process occurs. Harmful gases and particles collide with the liquid droplets. They are then absorbed or dissolved into the solution. This interaction effectively strips the pollutants from the airstream. The now-cleaned air continues onward, while the contaminated liquid collects for treatment.

Key Design Advantages of Wet Scrubbers

Wet scrubbers offer distinct benefits for complex industrial fumes. They handle high-temperature and high-humidity gas streams exceptionally well. Furthermore, they can simultaneously remove both particulate matter and gaseous pollutants. Their design also minimizes fire risks when dealing with combustible dusts. This makes them a preferred choice for many Wet Scrubber Manufacturers. For facilities searching for “Wet Scrubber Near Me,” understanding this technology is the first step.

Delving Deeper: Packed Bed Scrubber Efficiency

For applications requiring superior gas absorption, a specialized design excels. This design is the packed bed scrubber. Packed Bed Scrubber Manufacturers create units with a tower filled with “packing” material. This packing provides a massive surface area for gas-liquid contact.

Maximizing Surface Area for Cleanliness

The contaminated gas stream enters from the bottom of the tower. The scrubbing liquid gets distributed across the top of the packing material. As the liquid trickles down, the gas rises upwards. They meet in a counter-current flow within the packed bed. This creates an extremely long and turbulent contact path. Consequently, the absorption of acidic gases like HCl or SO₂ becomes remarkably efficient. This design is perfect for precise, high-efficiency air pollution control.

The Material Science Edge: FRP in Scrubber Construction

The choice of construction material is a critical scientific decision. This is where FRP Scrubber Manufacturers provide a significant advantage. FRP, or Fibre-Reinforced Plastic, is a composite material. It combines polymer resin with strong glass fibres. The result is a structure that is both incredibly robust and highly corrosion-resistant.

Why FRP Outperforms Traditional Materials

Metal scrubbers often suffer from rapid corrosion when exposed to acidic chemicals. FRP, however, is inherently inert to a vast range of corrosive agents. This leads to a dramatically longer system lifespan with minimal maintenance. Additionally, FRP is lighter than steel, simplifying installation and structural support. For these compelling reasons, leading Wet Scrubber Manufacturers increasingly utilize FRP. They choose it for durable and reliable system construction.

System Components: More Than Just a Scrubber

A complete Fume Extraction System is an integrated network of components. Each part plays a vital role in the overall scientific process. The capture hoods represent the starting point for containment. Ductwork acts as the dedicated roadway for transporting fumes. Then, the scrubber vessel serves as the primary cleaning station. An induced-draft fan provides the consistent negative pressure required. Finally, an exhaust stack releases the cleaned, compliant air safely into the atmosphere.

The Role of Fans and Airflow Dynamics

The fan is essentially the heart of the entire system. It creates the precise pressure differential needed to move air. Engineers must calculate the required airflow volume, or Cubic Feet per Minute (CFM). This calculation is based on the capture hood design and ductwork resistance. Proper fan selection ensures effective capture without wasting energy. Therefore, balanced system design is a crucial scientific endeavor.

The Science of Selecting the Right System

Choosing the correct system requires a detailed analysis of the pollutant. What is its chemical composition and concentration? What is the temperature and volume of the exhaust stream? Answering these questions determines the optimal scrubbing technology. For instance, acidic fumes need a basic scrubbing reagent like caustic soda. Particulate-laden smoke may require a different scrubber design altogether. UK Enviro Systems excels at this diagnostic phase. Our experts analyze your process to recommend a perfectly tailored solution.

Partnering with Expert Manufacturers

This is why partnering with experienced FRP Scrubber Manufacturers matters immensely. They possess the application knowledge to match technology to challenge. They understand the subtle science behind reagent selection and dwell times. Furthermore, reputable Packed Bed Scrubber Manufacturers can model absorption efficiency. They ensure your system meets specific emission standards before installation. Always look for manufacturers with proven expertise, not just generic equipment suppliers.

Maintenance: The Science of Sustained Performance

Even the best-engineered system needs regular care. Maintenance is the science of sustaining peak operational efficiency. It involves monitoring scrubbing liquid pH levels and reagent concentrations. It also requires inspecting nozzles for clogging and packing for fouling. Scheduled maintenance prevents unexpected failures and ensures continuous compliance. A reliable manufacturer will provide clear, scientific maintenance protocols.

Ensuring Long-Term Reliability

Think of maintenance as preventative medicine for your air quality system. Simple, consistent checks identify small issues early. This proactive approach avoids costly downtime and major repairs later. It also guarantees the system operates as designed for its full service life. Therefore, a strong partnership with your supplier is invaluable for ongoing support.

The Future of Fume Extraction Science

Technology in air pollution control continues to evolve. Innovations focus on reducing water usage and energy consumption. Additionally, smart sensors and IoT connectivity are becoming standard. These sensors provide real-time data on system performance and pollutant levels. This allows for predictive maintenance and even more precise control. Leading Wet Scrubber Manufacturers are already integrating these advances. They create smarter, more sustainable, and more efficient systems for the future.

Commitment to Cleaner Air and Safer Workplaces

The ultimate goal of this entire scientific process is profoundly human. It protects the health and safety of skilled workers in vital industries. It also safeguards our shared environment for future generations. Every well-designed Fume Extraction System represents a commitment to these principles. At UK Enviro Systems, we are proud to deliver on this commitment daily. We combine material science, chemical engineering, and practical expertise. We provide industries worldwide with the reliable, high-quality scrubbers they need.